| A tire is a pneumatic system, which supports a vehicle's load. It

does this by using compressed air inside to create tension in the carcass

plies. It is important to realize a tire carcass has a high tension

strength but has little or no compression strength. Stated another way,

it is hard to pull it apart but it squeezes together quite easily. It is

the air pressure that creates tension in the carcass and allows the tire

to function as a load-carrying device. That is why inflation is so

important. In an inflated, but unloaded tire, the cords pull equally on

the bead wire all around the tire. When a tire is loaded, the tension in

the cords between the rim and the ground is balanced or relieved. The

tension in other cords is not changed. Therefore, the cords opposite the

ground pull upwards on the bead. This is the mechanism that transmits the

pressure from the ground to the rim.

In addition, a tire must transmit handling (acceleration, braking, cornering) to the road. Cornering forces are transmitted to the rim in a similar manner to load. Acceleration and braking forces rely on the friction between the rim and the bead. Inflation pressure also supplies the clamping force, which creates friction. A tire also acts as a spring between the rim and the road. This spring characteristic is very important to the vehicle's ride. Too high an inflation pressure causes the tire to transmit shock loads to the suspension and reduces a tire's ability to withstand road impacts. Too low an inflation pressure reduces a tire's ability to support the vehicle's load and transmit cornering, braking, and acceleration forces. Temperature Effects: Air pressure is affected by temperature. The air

under pressure in a tire is no exception. Typically, an inflation

pressure can change by 1 psi for every 10 degrees Fahrenheit of

temperature change. Higher temperature means increased pressure. Proper inflation is the single most important factor in tire care. The

tire sidewall displays MAXIMUM pressure - based on MAXIMUM load capacity

of the tire. The inflation pressure displayed on the door jamb is the

RECOMMENDED pressure - based on normal load of a passenger car and MAXIMUM

load capacity of a pick-up truck. While a single pressure setting may be

okay for a passenger car, pick-up trucks by nature (especially 3/4- and

1-ton) vary greatly in weight. The recommended pressure setting for a

loaded truck will result in a grossly over inflated tire when the truck is

not loaded. Always check inflation when tires are COLD, that is when the

vehicle has been driven less than a mile, or at least one hour or more

after driving. Use a good quality tire pressure gauge. Note: It is

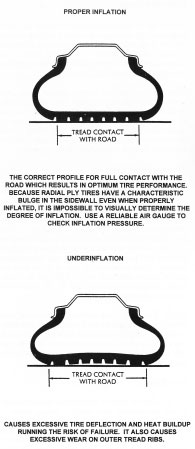

natural for radial tires to have a slight bulge in the sidewall at their

proper inflation pressure.

Proper Tire Inflation UNDER INFLATION Wear On Both Edges: Cause... "UNDER INFLATION" OVER INFLATION Tire footprint and traction are reduced when van, pickup, or RV tires are over inflated for the loads carried. In particular, tires with aggressive tread patterns may contribute to over steer or "road-walk" if inflated beyond the inflation pressure specified in the owner's manual and vehicle placard for standard or customary loads. Over inflation also increases the chances of bruise damage. Wear In Center: Cause... "OVER INFLATION"

CHECKING TIRE FOOTPRINT WITH A CHALK LINE

|

||||||||||